Food and Beverage fermentation

Since olden times people are using fermented products in their daily food consumption. There are many advantages of fermented foods such as they easily digestible and have improved flavour, texture and nutritive value. Some of the most commonly used fermented products are cheese, bread, yoghurt, sausages, soy sauce etc. With the advances made in microbiology and biotechnology, food and beverage fermentation and production has become a major industry. The food biotechnology has helped in improving the quality, nutrition value, safety and preservation of foods which in turn has helped in making these foods available through out the year.

Biotechnology can shorten the time spans that are intended to benefit the food industry. For example one of the commercially available enzyme can reduce the ripening period for cheddar cheese by almost 2 months that is almost 1/3rd that can save almost $ 50 million annually for this industry. The product is equally good in flavor and texture as the naturally matured cheese and can be produced in unlimited quantities. Unlike the rennin made from the stomachs of calves, the new products would hopefully be acceptable to vegetarians.

Another product, Whey, has tremendous potential as an excellent source of protein, a flavor enhancer, a binder in hamburgers, or as a substitute for egg whites in baking. One of the byproduct of whey is methane gas and about 8000 tons of cheese can produce about 80,000 tons of whey waste. This can produce 300 tons of protein and a volume of methane gas equivalent to 600 tons of crude oil.

Cheese

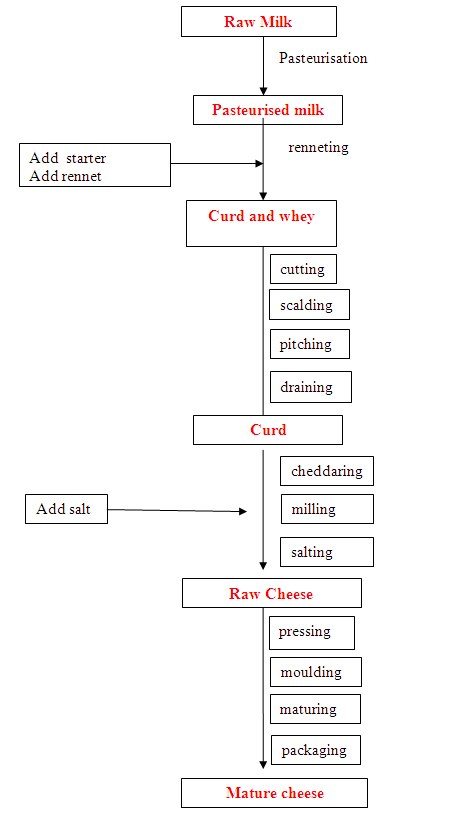

Cheese is made from the casein of milk that is produced after separating the whey –the liquid portion of the milk. The bacteria used in cheese making are either gas producers or acid producers. Gas producers release carbon dioxide, while the acid producers form lactic acid from lactose. It is the gas producers that determine the texture of a cheese and the acid producers determine the flavour. The cheese production involves the following steps:

a) Acidification of milk

b) Coagulum formation

c) Separation of curd from whey

d) Ripening of cheese.

Cheddar cheese is made from milk sterilized at 720C for 15 secs. A starter consisting of Streptococcus lactis is added and the milk is left to ripen for an hour. During the “ripening” the lactic acid content rises after which the milk is subjected to ‘renneting’. Rennet is a mixture of chymosin and pepsin from the stomach of a calf which coagulates the casein, the principal milk protein. There are several sources of rennet for cheese production. These include calves, adult cows, pigs, and fungal sources. Using genetic engineering, some workers have cloned the genes of animal chymosin and transfer the same into microorganisms. After renneting, a semi solid mass or ‘coagulum’ is formed consisting of water, fat and solutes trapped in a casein matrix.

The coagulum is cut into pea-sized pieces to separate it into small, creamy particles of curd suspended in a watery whey. ‘Scalding’ the mixture at 30-390C for 45 minutes is done to expel more whey and to change the texture of the curd. After the scalding, the curd is allowed to settle under gravity or ‘pitch’ and the whey is run off. After the formation of blocks of curd, the blocks are cut, stacked, drained and turned in a process called ‘cheddaring’. Following the cheddaring, the pH falls to 5.2 and the curd is ‘milled’ in to small pieces. In the final stages of preparation, salt is added which helps to preserve the finished cheese and bring out it’s flavour. ‘Ripening’ consists of storing the cheese under appropriate conditions so that bacteria and other microorganisms can cause chemical changes in the curd, improving and enhancing its flavour.

An outline of various stages in the manufacture of Cheddar cheese

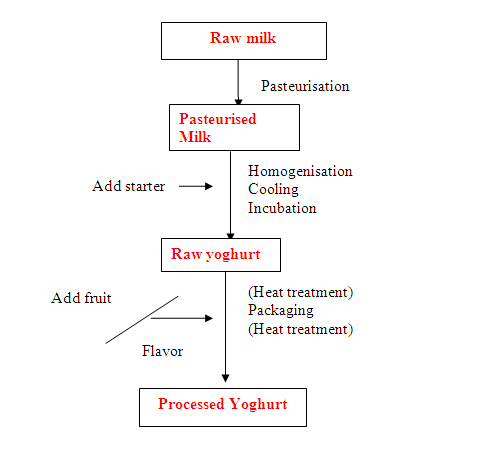

Yoghurt

Yoghurt is a sour milk product due to the presence of lactic acid yielded by bacteria that underwent fermentation. Bacteria that are commonly used in yoghurt production are Streptococcus thermophilus and Lactobacillus bulgaricus. which break down sugars in the milk and produce lactate or lactic acid as by-product.

Procedure to prepare Yoghurt in a Laboratory

Material Required

i) 1 liter homogenized pasteurized milk

ii) 30 grams skim milk powder (SMP)

iii) 100 grams refined sugar or brown sugar

iv) 80 ml starter culture bacteria from natural yoghurt

Preparation of Starter Culture

Take 3% skim milk powder in distilled water, yoghurt and incubate at 43o to 46o for 3 to 4 hours till set. In order to prepare flavored yoghurt add 200 grams of cooked pineapple pieces or strawberries.

Procedure

1. Take a clean and sterilized beaker and add the Skimmed milk powder and sugar. Dissolve the SMP and sugar in the milk. Heat it to 90oC by placing the beaker in a Hot water bath maintained at 90 C. Keep the beaker with the ingredients at this temperature for 10 minutes.

2. After 10 minutes, cool it to 50oC by placing it in a bath of ice water.

3. Meanwhile place the cooked pineapple/strawberries into the fermentation jar (2L beaker).

4. Now add the culture of the starter bacteria to the milk. Shake it well and get rid of lumps before adding to the milk.

5. Transfer the inoculated milk into the beaker or jar containing the cooked pineapple/strawberry pieces and then cover.

6. Incubate the milk for about 4 hours at 43oC to 46oC until thick and set. The clotting of the milk indicates the bacteria utilized the sugars and underwent fermentation.

7. Chill for at least 1-2 hours and then it is ready to be eaten.

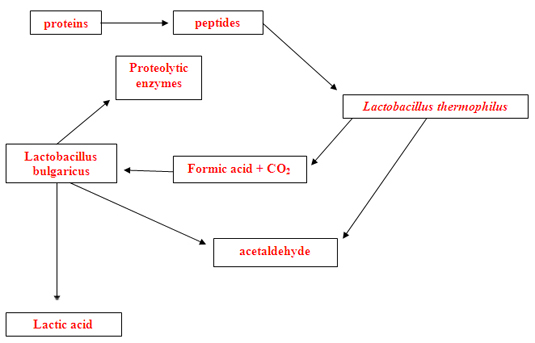

Two species of bacteria Lactobacillus bulgaricus and Lactococcus thermophilus in approximately equal proportions, are used to make yoghurt. Commercial producers pasteurize and homogenize the milk before adding the starter. After stirring, the mixture is then incubated for 3-6 hours at 40-450C. At this temperature the two bacteria have a mutually stimulating effect on one another. Proteolytic enzymes from L. bulgaricus break down milk proteins into peptides. These stimulate the growth of L. thermophilus which, in turn, produce formic acid and carbon dioxide, growth stimulants for L. bulgaricus. As the incubation proceeds, L. bulgaricus converts the lactose to lactic acid and the ph falls to 4.2-4.4 which leads to the coagulation of proteins by lactic acid and the thickening of the yoghurt. Further processing involves the addition of flavour, colour, fruit pulp and heat treatment to kill off any bacteria.

Metabolic products of bacteria used in yoghurt making

Stages in the manufacture of processed yoghurt

Preparation of Kimchi

Introduction

Kimchi is a traditional fermented vegetable of Korea, which is classified as pickled vegetables such as sauerkraut. Chinese cabbage or radish is widely used as the main source of Kimchi with various ingredients such as garlic, ginger and several fermented seafoods. The taste and fragrance of kimchi are chiefly dependent on the microflora that change during the fermentation which result in the liberation of free sugars, amino acids and organic acids. Microorganisms that are found to be involved in kimchi production include species belonging to the genera Lactobacillus, Streptococcus and Pseudomonas (Yun et al 1966).

Kimchi can be prepared at home. It is characterized by having a hot taste, which is attributed to the spices added. It is therefore consumed as an appetizer. It can also be prepared in the laboratory using the following method and materials.

Materials

i) 1 kilogram of head cabbage, Wok Bok cabbage, or pechay OR 2 medium sized radish

ii) 1 medium sized carrots

iii) ½ cup rock salt

iv) 4 cups cold water

v) ½ tsp. dried ground chili powder or chopped fresh pepper

vi) 1 tsp. refined sugar

vii) ½ MSG

viii) 1 pc. (1 sq. inch) fresh ginger (finely chopped) or ¼ tsp. dried ginger

ix) 6 stalks green onion (finely chopped)

x) wide mouthed jar or anaerobic fermentation jar

xi) (sterile)

xii) preserving jar

xiii) knife

xiv) clean chopping board

xv) pan/tray

xvi)graduated cylinder

Procedure

1. Cut head cabbage, Wok Bok cabbage or pechay diagonally into approximately 1-1.5 inch size pieces and place in a large pan. If radish is used, cut approximately 2 inches cylinder. Peel carrot and cut into desired size.

2. Dissolved ½ cup of rock salt in four cups of ice cold water.

3. Add the saline solution to the vegetable and mix thoroughly. Set aside. Mix the vegetables until the tissues are soften. Soak the vegetables for 2 to 4 hours in the brine. This step will eliminate possible harmful organisms, and will leave the halo tolerant organisms responsible for fermentation and flavor production.

4. Rinse or dealt the vegetable with cold water and drain.

5. Mix the rest of the ingredients thoroughly. Be sure all soluble ingredients like sugar and MSG are dissolved.

6. Add the seasonings to the vegetables and mix thoroughly.

7. Pack in jars or plastic containers with air tight cover. Ferment for 24 hours at room temperature (28-32C). Store in refrigerator.

Reference

Yun, J.W., S.C. Kang and S.K. Song. 1996. Mannitol accumulation during fermentation of Kimchi. Journal of Fermentation and Bioengineering. Vol. 81, No.3 , 279-280

Bread

The principal dry ingredients used in bread-making are wheat flour, salt, sugar, ascorbic acid, and the yeast Saccharomyces cerevisiae. Water or milk is added to produce a thick, sticky dough which is repeatedly folded or kneaded, to create nuclei for gas production and expansion. The mixed dough is rested, folded, and moulded and in a humid atmosphere at 34-350C, it is left for 10 minutes to ‘prove’. During the process of ‘proving’, fermentation of sugars in the dough, catalysed by enzymes from the yeast cells, produces carbon dioxide. As this gas cannot escapes from the sticky mass, it fills the gas nuclei and causes the dough to “rise” or increase in volume. This process is sometimes is called ‘leavening’. The overall effects of leavening are to make the dough lighter, more digestible, and of better flavour following from the production of organic acids, alcohols and esters by yeast cells. The role of enzymes in the process are summarized as follows:

maltase

a) Maltose ---------------› glucose

(in flour) (from yeast)

invertase

b) Sucrose-----------------› glucose + fructose

(added) (from yeast)

zymase

c) Glucose + fructose----------------› alcohol + carbon dioxide

(from yeast)

The yeast fermented bread have better flavour and texture as compared to the one prepared by using baking powder therefore in the commercial production of bread, Baker’s yeast is used. The living cells of aerobically grown Saccharomyces cerevisiae are collectively referred to as baker’s yeast. Baker’s yeast is commercially available either as a dried powder i.e. dry yeast with about 95% dry weight or in the form of cakes (about 25-30% dry weight). In recent years, some workers have reported the development of genetically engineered strains of Saccharomyces cerevisiae with improved fermentation properties.

Some other fermented products

Some of the fermented foods used worldwide are- rolls, cakes, soy sauce, idli and dosa (India), tempeh (Indonesia), Sauekraut (western countries). Sauekraut is a fermented and preserved form of cabbage mixed with salt. The pickles and chutneys (Sri Lanka, India, Pakistan) are also good examples of fermentation and preservation, based on the principles of biotechnology.

Sweeteners

The most commonly used natural sweetener is sucrose obtained from sugarcane, or beet and is used in a variety of food products like soft drinks, jams, jellies, sauces confectionery etc. Saccharin is a chemically synthesized sweetener which is 300 times sweeter than sucrose. However it is known to have some adverse health effects due to which its use is now restricted. High fructose corn syrup (HFCS) is produced from sucrose and is 1.5 times sweeter than sucrose. Using biotechnology, a low calories sweetener, Aspartame, has been created which is 200 times more sweeter, than sucrose and is being used as low calorie sweetener.

Thaumatin is a low calorie sweetener which is protein in nature and is 3000 times sweeter than sucrose. It has been extracted from the berries of the Thaumatococcus danielli which is a native plant in Africa. Biotechnological methods have been used to produce Thaumatin at a large scale to meet the high demands of consumption. Thaumatin- encoding mRNA species have been isolated, identified and converted to cDNA and finally to double stranded DNA. These DNAs were cloned and transferred to E. coli for the production of Thaumatin.

Monellin is another sweetener which is 100,000 times more sweeter than sucrose. It is a protein which is found in the fruit of an African plant Discorephyllum cumminsii and is composed of two chains- A-chain and B chain. It has been possible to chemically synthesize a gene that encodes both A and B chains as a single polypeptide.

Beverages

The use of fermentation procedures has been very common since times immemorial to produce alcoholic and non-alcoholic beverages. The most commonly used organism for the production of beverages is the yeast, Saccharomyces cerevisiae, which is capable of converting simple sugars to ethanol. There are two types of S. cerevisiae strains- bottom yeast and top yeast. The top yeast rises to the top while carrying out the fermentation and is used for the production of beer. The bottom yeast settles to the bottom during the fermentation and is used for the production of wine. The technique of recombinant DNA technology is being used to improve the strains of Saccharomyces cerevisiae to further improve the production yields of alcoholic beverages.

Beer

Beer is produced from barley grains, which contains mostly starch and proteins. There are several stages in the manufacture of beer.

a) Malting- It is the process of conversion of starch to maltose, and proteins to amino acids by steeping the dry grains in water. The excess water is drained and the soaked barley are incubated for 4-6 days to germinate. Enzymes produced during the germination, namely amylases and proteases, degrade stored materials in the grain into compounds that can be fermented by yeast. Germination is stopped by slowly heating the grains at 800C, temperature that is sufficient to destroy the enzymes. The grains that emerge from this process are known as malted barley.

b) Milling- the process of breaking each malted barley grain into 2-3 pieces is called milling. These crushed grains, or grist, are then fed into a ‘mash tun’, where mashing takes place. Hot water percolates through the grains, softening them, and extracting a nutrient-rich liquid called ‘wort’.

c) Boiling- it is the stage in which ‘wort’ mixed with hops is heated to a high temperature in a ‘launter tun’. Hops are the dried flowers obtained from hop plant to give added flavour, antiseptic properties, aroma and stabilizing effect to the beer. The resulting sterile liquid, after straining through a ‘hop-back’ is then allowed to cool.

d) Fermentation – The fermentation is carried out in open or closed bioreactors by adding pure strains of yeast S. cerevisiae at temperature 20–28°C for 5–10 days. As the fermentation of the beer proceeds, S. cerevisiae builds up at the bottom of the fermenter and at the surface of the ‘wort’ where it forms a crust. Carbon dioxide is prevented from escaping and so dissolves in the beer, making it effervescent.

e) Downstreaming – Downstreaming consists of flocculation, filtration, and maturation. A protein called isinglass, from the swim bladders of tropical fish, is added to flocculate yeast cells. Isinglass has an opposite electric charge to that of yeast cells, so the yeast cells are precipitated as a firm deposit leaving an almost clear liquid.

f) Filtration – Using filtration, any remaining yeast cells in the suspension are removed using a slurry of diatomite rock, layered to form a bed. Following filtration, the beer is allowed to stand for several weeks at 0°C until any cell debris or protein haze has cleared. This ‘chillproofing’ basically involves the removal of residual proteins suspended in the beer by precipitation or by employing proteolytic enzymes.

g) Finishing – This is the final stage in the production of beer and consists of packaging beer for sale to the public. Bottled and canned beers are usually pasteurized at 60°C to kill off any yeast cells that may still be present. In general, the alcohol (ethanol) content of beer is around 4–6% by volume, and ‘low alcohol’ beer may either be processed to remove most of the alcohol by osmosis or be a direct product of an engineered strain of yeast that produces alcohol in low concentration.

Wines

Wines are traditionally made from grapes, but can also be made from sugar-rich fruits, flowers or root crops, such as parsnips or carrots. In commercial winemaking, grapes are crushed between rollers then passed into a fermenting vat. The grape juice ready for fermentation process is technically referred to as ‘must’. Here sulphur dioxide- to prevent the growth of unwanted microorganisms – and yeast are added. The must in suitable bioreactors is bubbled with oxygen through the fermentation medium to promote the growth of yeast cells. The wine production process completes in 2-5 days. At the end of fermentation, wines are transferred to storage tanks or vats and allowed to age (which may take some months or years). ‘Ageing’ of wine is very important for the development of characteristic flavour and aroma. Table wines contain from 6-12% alcohol. Fortified wines, such as sherry, may contain as much as 20% alcohol. There are different types of wines- Red wine is derived from the black grapes, the White wine is derived from the black grapes after the removal of skins or white grapes. Dry wine is produced when sugars are completely fermented and contains higher alcohol content.

Vinegar

Vinegar is used to flavour the food and contains approximately 4% acetic acid. It is produced by a second fermentation of beer, cider, or wine. The second fermentation is aerobic and dependent on a mixed culture of Acetobacter , including A. scheutzenbachii, A. curium, and A. orleanse. In the presence of oxygen, these bacteria convert alcohol to acetic acid by the following route: Alcohol (ethanol)-------› acetaldehyde------› acetic acid

Miscellaneous microbially derived food products

There are large number of food products which are produced by the microorganisms such as single cell protein, mushrooms, vitamins, amino acids, organic acids, polysaccharides etc. Besides these, a variety of enzymes are also used in food and beverage biotechnology. Some of these enzymes are extracted from the microorganisms and others are extracted from other sources. These enzymes are extensively used in the food industry e.g. Proteases are used for tenderization of meat which leads to the flavouring of the meat besides easy digestion. The enzyme ‘lactase’ cleaves lactose to glucose and galactose which is easily assimilated by the body. This has helped to solve the problem of ‘lactose intolerance’ in humans. It has been estimated that lots of people around the world suffer from lactose intolerance which is caused due to the presence of 4-5% lactose in milk and whey. The people with ‘lactose intolerance’ develop diarrhea and suffer from abdominal cramps upon consuming milk and dairy products. The enzyme ‘lactase’ lowers the lactose concentration which helps these persons. The lactase enzyme is obtained from microbial sources e.g. Aspergillus niger.

Another example is the use of enzymes to clear the turbidity in the fruit juices caused due to the presence of pectins and cell debris. Enzyme preparation containing pectin esterase, polygalacturonase, pectin lyase, and hemicellulase is added to the fruit pulp for the removal of pectins and other turbid-causing agents.

The enzymes- glucose oxidase and catalase help to remove the glucose from the food stuff which increases the storability of these food items. The presence of glucose and oxygen causes the damage to these food items. The glucose from the egg white (used in baking) is also removed by using the same enzyme. The reaction is as follows:

Glucose + O2-------------› Gluconic acid + H2O2

2H2O2--------------------›2H2O + O2

Production of Edible Mushrooms

Mushrooms are fungi (class- basidiomycetes and ascomycetes) which can be cultivated on large scale for human consumption. Out of 4000 species, 200 are edible out of which only 12 species are cultivated on large scale. Some of the common edible mushroom varieties are- Agaricus bisporus (button mushroom), Pleurotus ostreatus (Oyster mushroom), Volvariella volvacea (Chinese mushroom). The edible mushrooms contain 35-45% protein, 7-10% fats and free fatty acids, 5-15% carbohydrates and minerals in good concentration. Therefore, edible mushrooms are also called vegetable meat. Edible mushroom cultivation has become one of the examples where microbial culture is being used for direct human consumption. Cultivation of edible mushrooms has become one of the most important and profitable biotechnological industry all around the world. Mushrooms have a short life 8-12 hours and should be therefore stored at low temperatures of 2-50C. Some of the mushrooms are cultivated in the summer and rainy season such as Volirariella sp. Agaricus bisporus and Pleurotus sp grow well in winters.

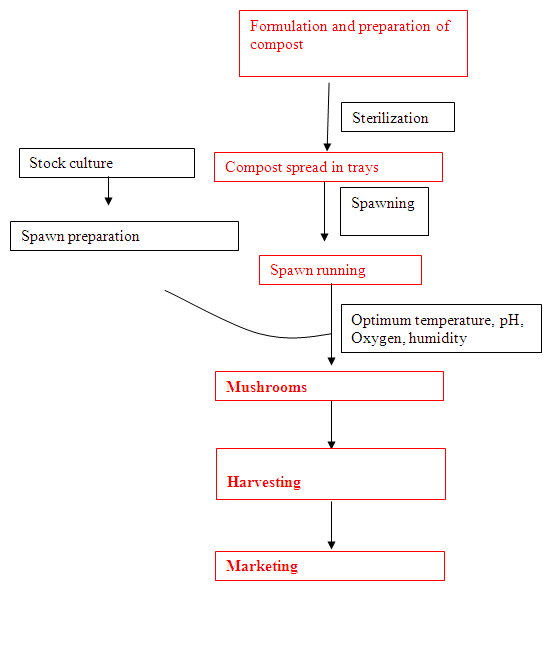

Process of mushroom production

The production of mushroom involves solid-substrate fermentation which is basically carried out by using substrates like straw, sawdust, compost, wooden logs etc. The compost with desired formulation is prepared and sterilized and then spread into trays which are then transferred to production room. This is followed by inoculation with spawn. ‘Spawn’ is the term used for the mushroom inoculums containing spores and/or small pieces of fruiting body. The culture is maintained at optimal growth conditions of temperature 150C and pH of 7.0. The humidity is maintained at 70-80% by watering the trays regularly. A single crop of mushroom is ready in 7-10 days. It is possible to have 3-4 crops before terminating the production process.

The outline of edible mushroom production

Microbial production of antibiotics

The chemical substances that can kill microorganisms or inhibit their growth are called antibiotics. These antibiotics are produced by the microorganisms or can also be chemically modified to make semi-synthetic antibiotics. Around 10,000 different antibiotics are known and 200-300 new ones are being added each year. A great majority of antibiotics are produced by actinomycetes particularly of the genus Streptomyces e.g. tetracyclines, actinomycin D. Among the fungi, the two groups Aspergillaceae and Moniliales are important for antibiotic production e.g. penicillin, cephalosporin, griseofulvin. The antibiotics are now routinely used to fight infections and thereby have contributed in increasing the life span of individuals.

It is important to select a high yielding strain and a suitable fermentation medium for microbial antibiotic production. Since antibiotics are the secondary metabolites of an organism, it is necessary to limit the growth of the microorganisms and to divert the organisms from primary to secondary metabolism. This is usually done by designing the medium in such a way that a key nutrient is exhausted at the appropriate time, producing the desirable metabolic diversion.

Based on their mode of action, they are classified in two groups :

A) Broad spectrum antibiotics are those antibiotics that can control the growth of several unrelated organisms e.g. tetracyclines, chloramphenicol.

B) Narrow spectrum antibiotics are those that are effective against selected species of bacteria e.g. penicillin, streptomycin.

For the commercial production of antibiotics, batch or fed batch fermentation methods are used. A small sample of the cultured stock is selected and amplified by growth on solid surfaces or in liquid culture. Spores o microorganism are retained in suspension form. This suspension is transferred into a container suitable for attachment to the fermenter. The fermenters are usually made up of stainless steel and are fitted with two or three flat impellers to cause agitation of the broth. The optimum temperature for antibiotic growth is between 24-280C. The entire process takes place in sterile conditions for which continuously steam is used. Sometimes, considerable amount of foam is generated during fermentation (when proteinacious media is used). To control the foam, antifoam chemicals such as vegetable oils are added to the medium.

The antibiotics are now being commercially produced world over. Antibiotics may be produced by microbial fermentation, or chemical synthesis, or a combination of both. The biotechnologists are making a lot of efforts to increase the fermentation yield and make profitable industrial ventures to obtain pure antibiotics. Among the various antibiotics, penicillin was the first product that was accidentally discovered by Alexander Fleming in 1928 from the fungus Penicillium notatum.

Penicillins

The basic structure of all the penicillins consists of a lactam ring and a thizolidine ring fused together to form 6-aminopenicillanic acid. Cloxacillin, ampicillin, floxacillin and azlocillin are some examples of semi-synthetic penicillins. The natural penicillins are effective against several Gram-positive bacteria by causing cell death by inhibiting the synthesis of cell wall (peptoglycans). However, natural penicillins are ineffective against microorganisms that produce beta-lactamase as this enzyme can hydrolyse penicillins e.g. Staphylococcus aureus.

Earlier Penicillium notatum was used for large scale production of penicillins however, now a days Penicillium chrysogenum and its improved mutant strains are preferred. Earlier the penicillin production was less than 2 untis/ml but with new strains, the production runs into several thousands of units/ml.

Using genetic engineering, genetic manipulations have been carried out to substantially increase the penicillin production e.g. extra genes coding for the enzymes cyclase and acyltransferase have been inserted into P. Chrysogenum.

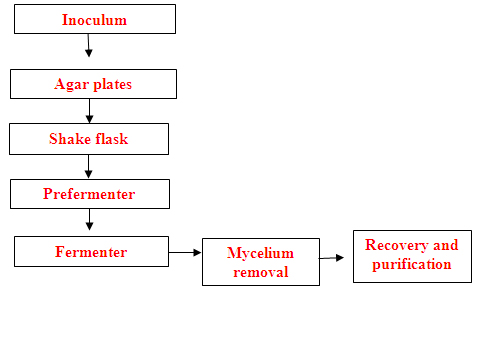

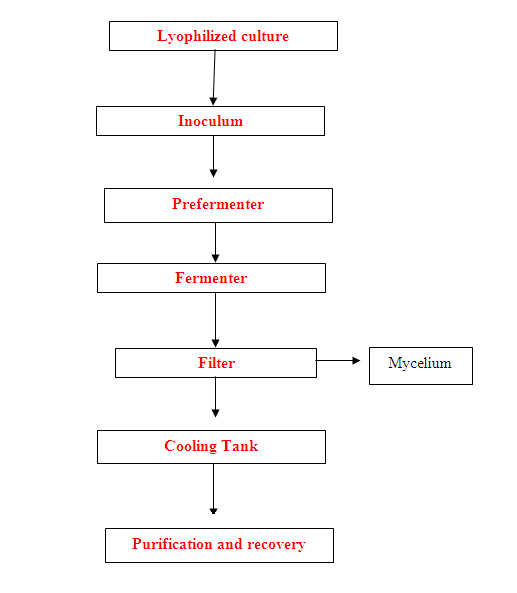

Production process of Penicillin

The penicillin production is an aerobic process therefore a continuous supply of oxygen to the growing cultures is a must. The growth phase is around 40 hours with a doubling time of 6-8 hours. After the growth phase is stabilized, the penicillin production exponentially increases with appropriate culture conditions. The penicillin production phase can be extended to 150-180 hours. During the entire process, pH is maintained at 6.5 and the optimal temperatures vary between25-270C. The culture medium consists of corn steep liquor (4-5% dry weight) and lactose for carbon source. The yeast extract, soy meal or whey is added to give good supply of nitrogen. Phenyl acetic acid or phenoxyacetic acid which serves as a precursor for penicillin biosynthesis is also continuously added.

For efficient synthesis of penicillin, the growth of an organism from spores must be in a loose form and not as pellets. Near the completion of the fermentation process, the process of extraction of penicillin from the broth starts. The mycelium is removed by filtration and penicillin is recovered by solvent extraction using n-butylacetate or methylketone at low temperature (<100 C) and acidic pH (<3.0). Further, the penicillin containing solvent is treated with activated carbon to remove impurities and pigments. The recovery of penicillin is done by adding potassium or sodium acetate. The potassium or sodium salts of penicillin can be further processed to remove impurities by using dry solvents such as n-butanol or isopropanol. These steps help in raising the yield of penicillin production to almost 90%. After the removal of water, penicillin salts are crystallized and dried under pressure which can later be converted into pharmaceutical dosage forms.

An outline of the flow chart for penicillin fermentation

Tetracyclines

Tetracyclines are broad spectrum antibiotics with widespread medical use. They are effective against Gram-negative and Gram positive bacteria, mycoplasmas, chlmydias rickettsias. Tetrcyclines inhibit the protein synthesis by blocking the binding of aminoacyl tRNA to ribosomes (A site). Chemically it is composed of a naphthacene ring-a four ring structure. The chlortetracycline and oxytetracycline are the two most commonly used in the treatment of human diseases. In 1945, the first tetracycline antibiotic was isolated from chlortetracycline from the cultures of Streptomyces aureofaciens. Using genetic engineering, high yielding strains of Streptomyces rimosus have been developed for increased synthesis of oxytetracycline. The biosynthetic pathway is very complex with almost 72 intermediates formed during the course of biosynthesis of chlortetracycline.

Production Process of Chlortetracycline

The ingredients like corn steep, liquor, soy flour or peanut meal is added to the fermentation medium as the suppliers of carbon and nitrogen. The addition of carbohydrates (glucose or starch) also helps in the good growth of the microorganisms and the production of antibiotic. To achieve higher yields and better production of chlortetracycline, the supply of ammonium and phosphate is maintained at low concentration. The optimum temperature for the growth is 27-300C, pH- 6.5-7.5 and aeration 0.8-1.0 vvm. The duration of fermentation is around 4 days. To recover the antibiotic, the culture broth is filtered at the end of fermentation process to remove the mycelium. The filtrate is treated with n-butanol or methylisobutylketone in acidic or alkaline condition for extracting the antibiotic. The process of adsorption to activated charcoal is done to remove other impurities. After the elution of chlortetracycline, it is crystallized.

The production chart for chlortetracycline